Application Summaries

At Mytex Polymers we understand that a project is not complete until a part has been manufactured, assembled and launched successfully. We have years of experience in developing products to meet new application needs, as well as finding ways to use existing grades to help reduce cost and weight or solve key functional requirements. Mytex Polymers compounds high-performance engineered polyolefin materials for a wide variety of applications. We develop, test and manufacture polymer solutions that are used in everything from automotive parts (both exterior and interior) to household appliances; from recreational vehicles and industrial equipment to specialty packaging.

We have created key application summaries to show the success we have had in new product/application development. Realizing it can be difficult to be the “first” customer to try a new product idea, these success stories are to show that these have been done. Using these best practice ideas can help a company look for similar ways they can be successful moving forward.

DuraFlex 6120

bedrail & tailgate covers for pickup trucks

DuraFlex 6120 was developed to meet multiple OEM requirements for the pickup truck market. This material has excellent performance in all exterior scratch and mar durability requirements and does not whiten after rigorous application testing.

key material advantages

- Good Processability for Long Thin Parts - Minimizes Part Warpage

- Excellent Surface Durability for Scratch and Mar

- UV Stabile to 4500kJ

- Colorable to OEM Requirements

- Low CLTE for Excellent Part Performance and Gap Tolerances

- Excellent Cold Temperature Impact

Download the DuraFlex 6120 Application Summary

DynaFlow 5160 MIC

heavy truck interior applications

DynaFlow 5160 is a molded in color material that was developed for Heavy Truck interior applications. This material is a cost savings from the incumbent PC/ASA materials that have been used for these applications. This product has similar shrinkage to PC/ASA and most times can be used in existing tooling with little to no modifications. This product has improved scratch and mar resistance and the natural dead sound characteristics of olefinic materials helps reduce squeak and rattle.

key material advantages

- Scratch and Mar Resistance

- Stiffness/Impact Balance

- Similar Shrinkage to Engineering Alloy Equivalents

- Chemical Resistance

- Weatherability

- Low CLTE

- Reduced Noise

- Recyclable

- Does Not Need to be Dried

Download the DynaFlow 5160 MIC Application Summary

DynaFlow 5270

fascia grille & bumper supports

DynaFlow is an engineered polyolefin that was developed to compete against current applications being molded in PC/ABS and/or PC/ASA. This material can be molded in color or used for non color critical parts. The AMMS (As Molded Mold Shrink) of this product matches many engineering alloy products and can be trialled in current tools for immediate cost savings. This olefinic material is also recyclable and scrap can be added back into production parts.

key material advantages

- Increased Processability vs. Engineering Alloys

- Stiffness/Impact Balance

- Similar Shrinkage to Engineering Alloy Equivalents

- Chemical Resistance

- Improved HDT (@0.45MPa)

- Lower CLTE (~35% lower)

- Recyclable

- Does Not Need to be Dried

Download the DynaFlow 5270 Application Summary

AS67KW-01US

automotive interior

AS67KW-01US is a molded in color material that was developed for automotive interior applications. This material has excellent cold temperature ductility and is used on applications which come in contact with airbag deployments. This resin has been designed to be laser scorable and has the highest scratch resistance for improved surface durability. This product is molded in color and has been matched to many of the OEM colors. As with most olefins, the applications are sound dead and reduce noise from squeak and rattle.

key material advantages

- Scratch and Mar Resistance

- Stiffness/Impact Balance

- Similar Shrinkage to Engineering Alloy Equivalents

- Chemical Resistance

- Weatherability

- Low CLTE

- Reduced Noise

Download the AS67KW-01US Application Summary

AS199LW-01US

fascia grille & bumper supports

DynaFlow is an engineered polyolefin that was developed to compete against current applications being molded in PC/ABS and/or PC/ASA. This material can be molded in color or used for non color critical parts. The AMMS (As Molded Mold Shrink) of this product matches many engineering alloy products and can be trialled in current tools for immediate cost savings. This olefinic material is also recyclable and scrap can be added back into production parts.

key material advantages

- Increased Processability vs. Engineering Alloys

- Stiffness/Impact Balance

- Similar Shrinkage to Engineering Alloy Equivalents

- Chemical Resistance

- Improved HDT (@0.45MPa)

- Lower CLTE (~35% lower)

- Recyclable

- Does Not Need to be Dried

Download the AS199LW-01US Application Summary

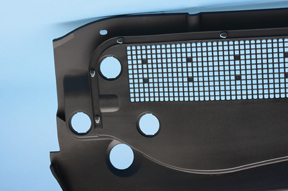

AS149 LW

cowl vent grilles/leaf screens

Mytex AS149LW is an engineered polyolefin that was developed to be used for Cowl Vent Grille applications. This resin has years of commercial success. The high flow characteristics help fill these large applications through difficult vent meshing. The material also has been designed for optimal weathering and is also recyclable so scrap can be added back into production parts.

key material advantages

- Increased Processability for Large Flow Distances

- Dimensionally Stable for Large Application Tolerances

- Superior Weathering Characteristics for Horizontal Surfaces

- Chemical Resistance

- Recyclable

- Does Not Need to be Dried

Download the AS149 LW Application Summary